Elevated upfront expenses, complicated implementation, and prolonged ROI persist: these misunderstandings continue to be the main obstacles to artificial intelligence adoption in manufacturing. Although the majority of technology providers endorse cloud-based solutions, a different strategy is surfacing: the phased adoption of AI, beginning at the component level. This approach allows manufacturers, regardless of size, to utilize AI capabilities efficiently without substantial initial costs.

Intelligence on the component scale

A large percentage of manufacturing plant breakdowns can be anticipated by analyzing data from separate components. Sophisticated but easy-to-use analytics at the servo drive level facilitate self-assessment and identification of possible problems in adjacent machine components. Frequency inverters employ AI algorithms to identify the underlying reasons for failures, whereas industrial robots optimize their trajectories in real-time, greatly increasing efficiency and enhancing quality.

A key aspect of this method is the capability to react immediately to equipment irregularities or foresee them beforehand. Smart elements process data instantly, allowing quick modifications to parameters or the deactivation of machines to prevent significant failures.

“According to feedback from numerous manufacturing facilities of various sizes, we understand that components featuring AI-driven intelligence significantly decrease unplanned downtime.” “This kind of analysis occurs automatically and does not necessitate any expertise in data science,” says Piotr Siwek, Digital Director EMEA at Mitsubishi Electric Factory Automation.

From intelligent components to smart factory

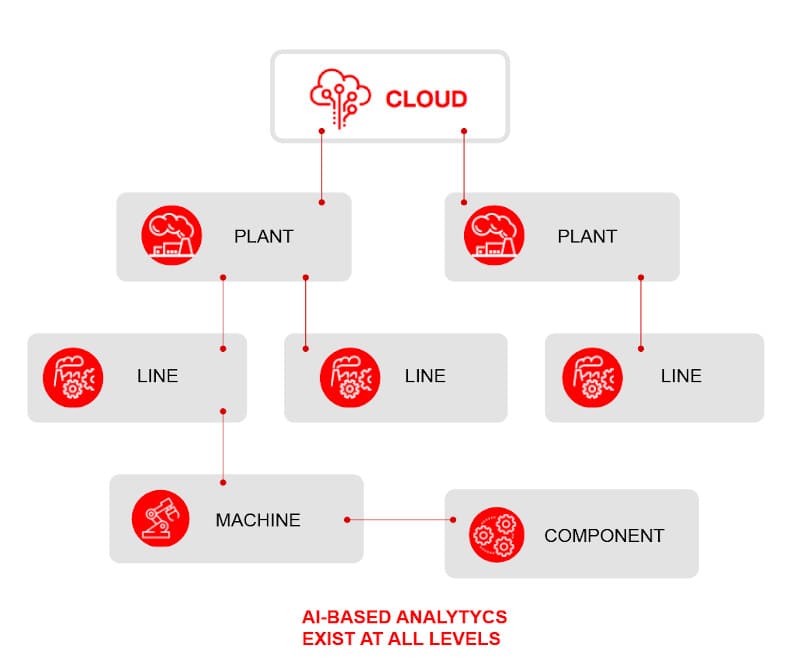

The scalability of this approach to AI implementation significantly reduces deployment costs compared to comprehensive cloud solutions. After implementing intelligence on the component level, whole production lines can benefit from data analysis by integrating PLC control systems with AI algorithms. As factories face increasing demands for data analytics, edge-level solutions can be deployed while keeping all the factory data in-house.

A significant advantage of this approach is enhanced data security. Local processing minimises the risk of cyber-attacks and data breaches, which is particularly crucial for manufacturing facilities working with sensitive data or technologies.

“The key to success is starting with small, measurable projects. In one European factory, we began with AI implementation in welding applications. Edge-level data analytics performed with MaiLab achieved nearly 100% accuracy of failure predictions. The quality results encouraged the client to expand the project across the entire production line”, adds Siwek.

When cloud makes sense

Industry experts predict the growing importance of hybrid AI solutions, combining component-level analytics with selective cloud utilisation. Cloud solutions excel in cases requiring historical data analysis across multiple facilities or supply chain optimisation.

The cloud offers unparalleled capabilities in advanced big data analytics and machine learning on large datasets. It is particularly valuable for global organisations needing to compare and optimise processes across multiple locations simultaneously. “The future belongs to hybrid solutions. Our bottom-up strategy allows clients to build solid digital foundations and consciously choose which processes require cloud support”, summarises Siwek.

The future is scalable

The evolutionary approach to industrial AI implementation, beginning at the component level, presents a practical alternative to comprehensive cloud deployments. It enables the gradual development of digital competencies, reduces investment risk, and ensures quick returns. As both organisations and their analytical needs grow, the system can be expanded with additional layers, including selective cloud utilisation where it brings the most value.