Automated handling is evolving to be more adaptable, quicker, and smarter: At automatica (June 24-27, Munich), Schmalz will showcase new gripping systems and vacuum generators in Hall A5 at Stand 301. Exoskeletons will also be showcased, allowing workers to handle heavy workpieces with ease.

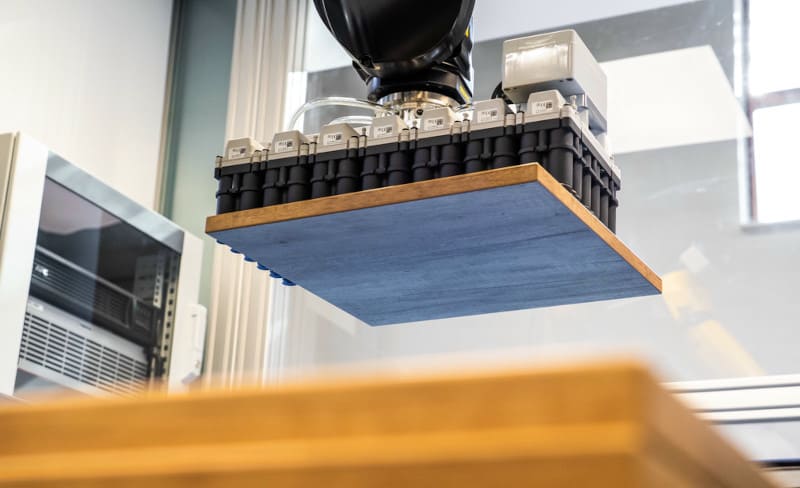

Through the Solution Kits ivOS, Schmalz facilitates the creation of tailored, automated handling solutions for specific applications. The integration of a vacuum gripping system, a 3D camera, and AI-enhanced software identifies, grabs, and transfers unfamiliar and diverse workpieces – starting from batch size 1. The logistics versions (rapid picking) and the sheet metal versions for handling sheet metal are complemented by the new Solution Kit ivOS Wood. It is customized to meet the needs of furniture production firms and handles the loading and unloading of CNC, drilling, and other machinery, for instance. The processes of painting can be automated and significantly enhanced in efficiency, just as the removal of individual components from nesting machines can be improved. Joineries relieve their employees from tedious duties while also addressing the lack of qualified labor.

Benefits of electrical vacuum creation

Along with tested pneumatic vacuum generators, Schmalz will showcase groundbreaking purely electrical systems for automated handling at its exhibit. For the first time, the company will present the lightweight layer gripper ZLW featuring electric vacuum generation – perfect for handling entire layers of items like glass, cans, or cardboard boxes. The Compact-Pump GCPi double-head diaphragm pump, paired with the LQEi compact valve, allows for notably brief cycle times owing to pre-evacuation and rapid venting—similar to pneumatic systems. The compact vacuum generator ECBPMi is installed directly on the end of the arm and, due to its diameter, is perfectly compatible with standard robotic arms.

Efficient material handling with vacuum grippers

Schmalz focuses on high efficiency with the new area grippers FA-X: the system reduces compressed air consumption by 80 percent. The grippers are used for palletizing, depalletizing, picking or sorting cardboard boxes, sheet metal, wood or plastic workpieces.

In the food industry in particular, companies have to pick and pack products that have delicate surfaces and can vary greatly in shape – from chicken drumsticks and peppers to soft donuts. The finger gripper mGrip adapts to all objects thanks to circular or parallel grippers and different finger module sizes. Hygienic design and IP69K certification ensure that the system can withstand high temperatures or high-pressure water and protects against the ingress of dust. As a result, the finger gripper is easy to clean – it is designed for both clean-in-place (CIP) and clean-out-of-place (COP) processes. Such adaptable systems are also used in other industries, for example when handling nets or bags with small parts. They enable fast and continuous picking without the need for personnel to be constantly available.

Keep your back free

The forward bend exoskeleton MATE UBA supports the lower back when lifting and depositing goods – especially during repetitive tasks, for example when employees remove goods from low shelves. The upper body exoskeleton MATE UTA relieves strain on people when carrying out overhead work such as mounting plasterboard on ceilings or loading and unloading freight containers stacked at a height. The systems do not require an external energy source, they are lightweight and suitable for outdoor use.

Also on display is the tried-and-tested JumboFlex vacuum tube lifter, which Schmalz has redesigned. Its handle now fits even better in the hand – regardless of its size. It is intuitive to use and significantly reduces the training time for new skilled workers.

Schmalz at automatica: Hall A5, Stand 301