The upcoming era of metalworking is adaptable, accurate, and automated. During EMO Hannover 2025, SCHUNK will showcase how adaptable clamping systems, modular automation strategies, and worldwide engineering knowledge assist businesses in enhancing their processes for efficiency and sustainability.

How can businesses safeguard their operations amidst global unpredictability, heightened competition and cost challenges, and a lack of skilled labor? This question is increasingly on the minds of individuals in the metalworking sector. EMO Hannover, the premier global trade fair for production technology, aims to offer several solutions. At the SCHUNK exhibit, attendees can look forward to hands-on production modules that simplify, enhance flexibility, and improve resource efficiency in parts handling and machine processing

Effective automation of the machine tool

Automated loading and unloading serves as a crucial tool for enhancing productivity and efficiency within the manufacturing process. But which automation system is ideal for which manufacturing method? The application specialist delivers guidance and presents a variety of automation solutions that are specifically customized to meet the needs regarding batch sizes, workpieces, and production processes. The emphasis is not solely on supplying users with the appropriate components but also on assisting them with solid knowledge and the correct steps from the beginning.

Innovative clamping options for varied uses

Alongside automation, SCHUNK provides all modules for adaptable and efficient workpiece clamping within the machine. For machining intricate workpieces or small production runs, the company is introducing innovative clamping solutions designed specifically for the needs of versatile manufacturing settings

With the KONTEC KSC-5X , SCHUNK is expanding its family of 5-axis vises with a high-performance centric clamping vise. It has been especially developed for demanding machining operations. Its higher base jaws, combined with a selection of system and top jaws that is unique on the market, enable complex workpieces to be clamped with optimum accessibility. Thanks to a spindle quick-change system, the vise can be quickly and easily adjusted to new clamping tasks. Thanks to the integrated interface of the quick-change pallet system, it fits seamlessly into the extensive modular clamping technology system, which enables a wide range of possible combinations for highly efficient workpiece clamping.

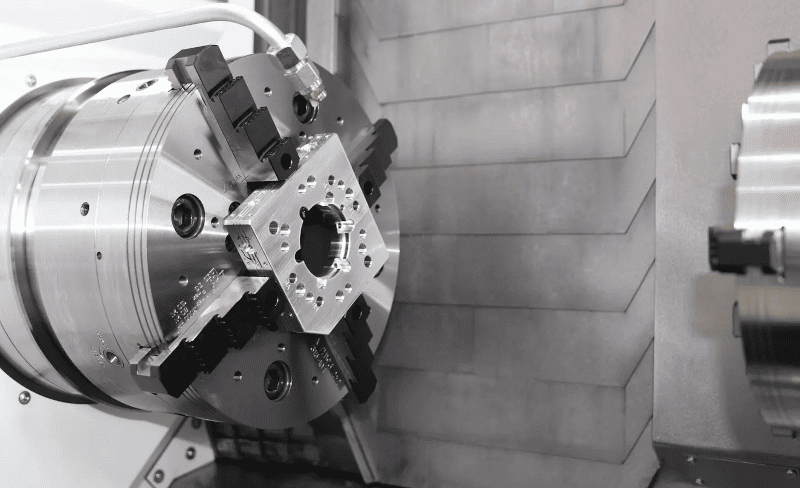

SCHUNK is also clearly moving in the direction of flexibility with its lathe chucks. Following on from the manual chucks, a 2+2 jaw compensation chuck is now also available for power chucks. Thanks to its innovative drive concept, the new ROTA THW3 2+2 power chuck enables the centrically compensating workpiece clamping of any geometry – from round and cubic to bulky parts. Equipped with a patented seal and permanent lubrication as well as a jaw quick-change system, it manages the balancing act between low maintenance and short set-up times while offering consistently high clamping forces.

Customized with SCHUNK Engineering

Every production process is unique, and standard solutions are not always the best choice. SCHUNK supports users with a structured process for the development of customized solutions. SCHUNK accompanies its customers from the precise definition of requirements through design, to production and integration – and thus creates bespoke solutions that are precisely tailored to their production requirements in various industries. For example, precisely fitting hydraulic clamping devices for turbine rotors in the aerospace industry are validated and optimized using digital simulation tools.

Standardized turnkey solution

While customized developments are indispensable for complex requirements, small and medium-sized companies in particular require practical concepts that can be implemented quickly. This is where SCHUNK comes in with the new modular GROW automation cells . These turnkey, CE-certified complete solutions are intuitive, flexibly adaptable and have been specially designed to automate manufacturing processes quickly and efficiently. Whether for laser marking or part separation – GROW enables companies to optimize their production without extensive prior knowledge and to benefit from high reliability and scalability.

Data-based process control in real time

With the increase in automation and the digitalization of machine tools, the focus is increasingly shifting to the intelligent monitoring of processes. Electrical and sensor-based clamping systems from SCHUNK make it possible to monitor the process-relevant status of the clamping devices and workpieces or the vibration behavior of the tools in real time. As a result, they not only offer greater safety and end-to-end transparency, but also simple integration into existing machine control systems – an important basis for the production of the future. An absolute highlight will be the battery-operated clamping devices, which can be integrated wirelessly, e.g. by radio, via solutions from common measuring system providers or via IO-Link wireless. Visitors will have the chance to see the benefits of these technologies for themselves in a live demonstration at the SCHUNK booth.