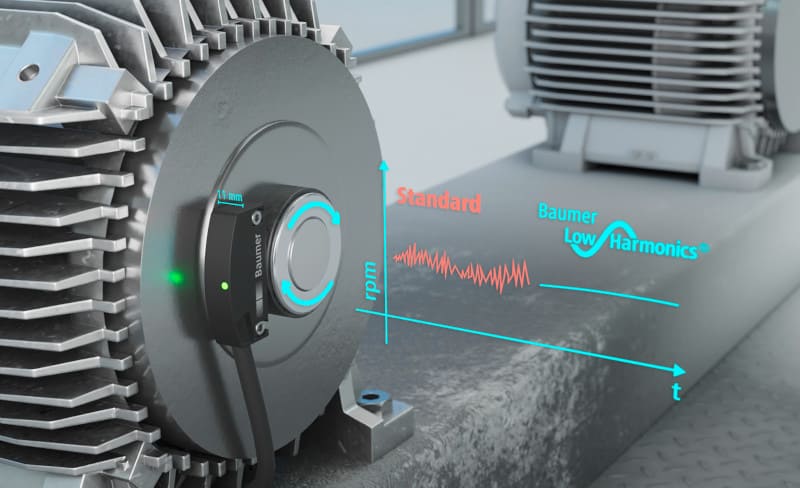

Baumer unlocks fresh opportunities in drive technology and factory automation through its groundbreaking LowHarmonics encoder technology. The EB260 compact incremental magnetic ring encoder is the initial product offered with this groundbreaking signal processing technology.

The bearingless encoder combines the accuracy of optical detection with the resilience and affordability of magnetic systems – all while occupying minimal installation space. LowHarmonics signal processing featuring auto-calibration removes signal inaccuracies caused by installation, temperature variations, aging, and mechanical influences to guarantee optimal precision and control performance. The built-in air gap monitor constantly measures the distance to the magnetic rotor. Any minor alteration due to damage to the machine’s mechanics is tracked and communicated to the upper-level system.

The EB260 magnetic encoder is highly durable due to its bearingless construction and hermetically sealed electronics. The operation is completely free from wear, with no self-heating, and the encoder is resistant to shaft currents, significant shocks, and shaft movements. Adjustable shaft diameters and only 11 mm of installation depth allow for exceptionally compact integration, while the remarkable measuring accuracy creates new application possibilities in drive technology and industrial automation.

An additional advantage of the compact, high-performance encoder is its configuration adaptability. The intuitive Baumer Sensor Suite powers this software, featuring a configurable motion monitor, switching output, and square-wave, sine/cosine, and IO-Link interfaces.

With EB260, Baumer is strengthening its commitment to providing maximum customer benefit as a leader in technology. The groundbreaking encoder series EB260 and EB260F introduces a new product family featuring cutting-edge technology for intelligent automation to the unmatched extensive Baumer encoder lineup.